Gasification: A novel way to handle our waste

By Aparna Mele

We produce over 2 billion tons of waste per year, a number that’s expected to grow by 70% by 2050. We have long sought ways to turn all this waste into energy, but this has usually meant incineration – that is, burning our trash – a method that many environmentalists say is far too polluting. While recycling has become more deep-rooted in public culture, two-thirds of household waste still ends up in landfills. Therefore, conventional recycling strategies are not the complete answer. A better solution may lie in gasification, a thermo-chemical technology that advocates are trying to repurpose as a way to deal with our waste. This process essentially “cooks” biomass in an oxygen-starved environment. Without sufficient oxygen, the material does not burn, but gives off a hydrogen-rich gas, while the biomass converted into solid carbon. The “syngas” given off in the process is cooled and cleaned, and can be used as a substitute natural gas to create electricity or liquid fuels. Gasification companies don’t burn trash and combustion is not performed; instead they turn into a synthetic gas, in a process they say is both economical and eco-friendly, because it does not produce harmful byproducts like dioxins. Instead, the syngas produced can be used as fuel or sold to industry, a groundbreaking recycling feat that has brought plasma gasification increased attention nationwide.

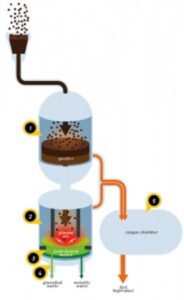

Here is a step-by-step overview of the process:

From the Wired article (https://www.wired.com/magazine/2012/01/ff_trashblaster/all/)\

- Gasification: The waste is shredded and travels to the top of a large tank, mixing with steam and oxygen and falling into a 1,500 degree Fahrenheit furnace. This gasification transforms a majority of the waste into a mixture of gases that heads to the syngas chamber.

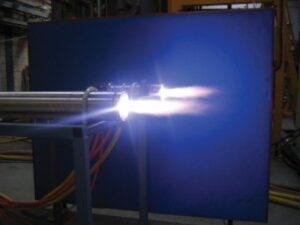

- Plasma Blasting: The undestroyed material enters another specially insulated cauldron where two electrodes create an electric arc (akin to a bolt of lightning) that produces a stream of plasma, breaking down the gases into their constituent atomic components and producing more syngas.

- Hazardous Material Collection: A joule-heated melter sits at the bottom of the second cauldron and traps any hazardous material left over from the plasma-blasting in a slurry with molten glass.

- Recycling: The slurry is drawn out of the system and becomes inert. In this state, the molten glass can be converted into low-value materials like road aggregate. Any metals are also captured here and later recycled into steel and other products.

- Fuel Capture: The syngas captured consists mostly of hydrogen and carbon monoxide. After purification, it can either produce electricity or be sold and converted to fuels.

Two electrodes can create an electric arc of plasma, which has a unique ability to break gases down into their constituent atoms.

Any hazardous material that escapes destruction by the plasma heater falls into a slurry with molten glass. This slurry is slowly drawn out and cools to become inert, when it can then be converted into low-value materials such as road aggregate.

This synthetic gas can then be converted into a wide variety of end products like electricity, diesel fuel, hydrogen fuel, or ethanol, Because the process of gasification converts organic materials into carbon monoxide, carbon dioxide and hydrogen gas. This process is widely used on industrial scales for the generation of electricity from fossil fuels. A wide variety of biomass and waste-derived feedstock can be gasified, including wood waste, plastics, aluminum, municipal solid waste (MSW), agricultural and industrial wastes, sewage sludge and crop residues.

The gasification of waste has numerous environmental advantages over incineration and other technologies. Gasification plants produce significantly lower quantities of air pollutants. The process uses a smaller amount of air, resulting in higher energy recovery efficiency and limited formation of pollutants like nitrogen oxides. The process reduces the environmental impact of waste disposal because it allows for the use of waste products as a feedstock. Gasification plants also use less water than traditional coal-based power plants. The by-products of gasification are non-hazardous and readily marketable. Gasification is not only beneficial to the environment, but also economically advantageous. This process can effectively compete in high-price energy environments to provide both power and products. Gasification can be utilized to turn lower-priced feedstock, such as pet coke and coal, into valuable products, like electricity, fuels and fertilizers. The operating costs of a gasification power plant are lower than conventional coal-fired plants and require less pollution control equipment. A gasification plant also offers wide fuel flexibility, as it can vary a mix of solid feedstock or run on a gas or liquid feedstock, allowing the operator more freedom to adjust to the price and availability of various kinds of feedstock.

Because of drought and climate change, there is a large amount of biomass out there now. Gasifying biomass rids forests and fields of materials that would otherwise rot and produce methane or help fuel wildfires. Wildfires regularly threaten lives and property, cost untold millions to control and clean up, and greatly contribute to poor air quality and climate change. It is a cleaner way of producing renewable energy — gasification plants are considered carbon-negative because they produce solid carbon instead of CO2. Gasification also produces biochar, a soil amendment that helps increase crop yield, refreshes worn out soils, retains soil moisture, reduces the need for fertilizers and sequesters carbon that would otherwise be emitted as greenhouse gases.

Theoretically, the process seems foolproof because all byproducts of the reactions are dealt with and useful resources are generated. However, some environmentalists believe this efficiency discourages recycling and the development of renewable products, while encouraging more apathy toward trash. They argue that the best way to move away from waste plastics isn’t to find new, creative things to do with them once they become waste, it is to just move away from using them altogether.

Regardless, it is refreshing to see waste and refusal industries keep the environment in mind when handling our amasses trash and looking for innovative ways to reduce our greenhouse effect!

Resources:

Yale Scientific April 3, 2013

Waste Advantage Oct 30, 2015